Ford 6.7 Powerstroke Engine: Everything You Need To Know

The Ford 6.7 Powerstroke engine has become a cornerstone of the Ford heavy-duty truck lineup, known for its impressive power, reliability, and innovative design. Since its introduction in 2011, this engine has undergone several iterations, each bringing performance, efficiency, and technology improvements. Introduction and Historical Context The 6.7 Powerstroke marked a significant milestone for Ford, […]

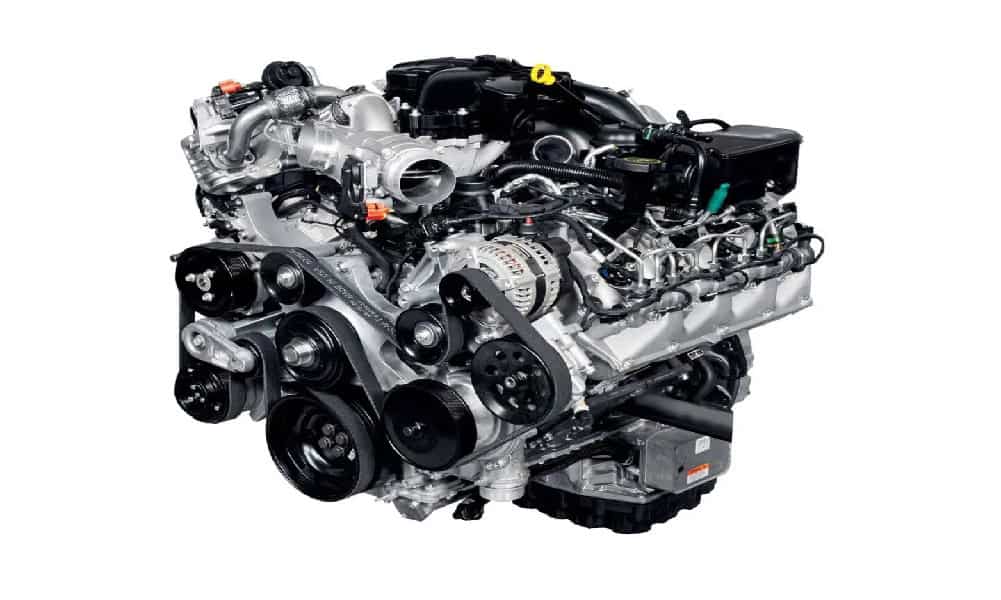

The Ford 6.7 Powerstroke engine has become a cornerstone of the Ford heavy-duty truck lineup, known for its impressive power, reliability, and innovative design. Since its introduction in 2011, this engine has undergone several iterations, each bringing performance, efficiency, and technology improvements.

Introduction and Historical Context

The 6.7 Powerstroke marked a significant milestone for Ford, as it was the first Power Stroke diesel engine designed and produced entirely in-house. This move away from the previous partnership with Navistar International allowed Ford to have complete control over the engine’s design and production, tailoring it specifically to meet the demands of their Super Duty truck line.

Introduced for the 2011 model year, the 6.7 Powerstroke replaced the 6.4L Power Stroke, addressing many reliability issues that had plagued its predecessor. The engine was under the codename “Scorpion,” a nod to its unique reversed architecture design.

Engine Specifications and Design

The 6.7 Powerstroke is a 6.7-liter, V8 turbocharged diesel engine with several distinctive features:

- Displacement: 6.7 liters (409 cubic inches)

- Configuration: V8 with a 90-degree angle between cylinder banks

- Bore x Stroke: 99 mm x 108 mm (3.90 in x 4.25 in)

- Compression Ratio: 16.2:1

- Valvetrain: OHV (Overhead Valve) with 4 valves per cylinder

- Block Material: Compacted Graphite Iron (CGI)

- Cylinder Head Material: Aluminum alloy

Unique Design Features

The 6.7 Powerstroke introduced several innovative design elements:

- Reverse-Flow Layout: Unlike traditional diesel engines, the 6.7 Powerstroke features an unconventional layout where the exhaust manifolds are in the valley of the V, with the intake manifolds on the outside. This design allows for shorter exhaust routing to the turbocharger, improving throttle response and reducing heat transfer to the engine bay.

- Compacted Graphite Iron Block: The use of CGI for the engine block provides superior strength compared to traditional cast iron while being lighter, allowing for a more robust design that can handle higher cylinder pressures.

- Single Sequential Turbocharger: Initially, the engine used a unique single sequential turbocharger with dual compressor wheels, later replaced by a more conventional variable geometry turbocharger in later iterations.

- High-Pressure Common Rail Fuel System: The engine employs a Bosch high-pressure common rail system capable of multiple injection events per cycle, improving combustion efficiency and reducing noise.

Performance Evolution

The 6.7 Powerstroke has seen significant performance improvements since its introduction:

First Generation (2011-2014)

- Initial Output: 290 kW (390 hp) and 997 Nm (735 lb-ft) of torque

- Mid-2011 Update: 298 kW (400 hp) and 1084 Nm (800 lb-ft) of torque

Second Generation (2015-2019)

- 2015 Model Year: 328 kW (440 hp) and 1166 Nm (860 lb-ft) of torque

- 2017 Model Year: 328 kW (440 hp) and 1254 Nm (925 lb-ft) of torque

- 2018 Model Year: 336 kW (450 hp) and 1268 Nm (935 lb-ft) of torque

Third Generation (2020+)

- 2020 Model Year: 354 kW (475 hp) and 1424 Nm (1050 lb-ft) of torque

These improvements have kept the 6.7 Powerstroke competitive in the heavy-duty truck market, often leading the class in power and torque figures.

Technological Advancements

Throughout its generations, the 6.7 Powerstroke has incorporated several technological advancements:

- Piezoelectric Fuel Injectors: These advanced injectors allow for precise fuel delivery with up to five injection events per combustion cycle, improving efficiency and reducing emissions.

- Variable Geometry Turbocharger: Introduced in the second generation, this design provides better low-end response and overall performance than the original dual-compressor design.

- Selective Catalytic Reduction (SCR): This emissions control technology uses Diesel Exhaust Fluid (DEF) to reduce NOx emissions, helping the engine meet stringent emissions standards.

- Compacted Graphite Iron Block: The use of CGI allows for a stronger, lighter engine block that can withstand higher cylinder pressures, enabling increased power output in later generations.

- Advanced EGR System: The exhaust gas recirculation system helps reduce emissions while maintaining performance.

Fuel Efficiency and Emissions

The 6.7 Powerstroke has made significant strides in fuel efficiency and emissions reduction:

- Fuel Efficiency: While specific fuel consumption figures vary based on vehicle configuration and use, the 6.7 Powerstroke is known for its relatively good fuel economy, considering its power output. The engine’s efficient design and advanced fuel injection system contribute to this performance.

- Emissions Control: The engine meets stringent emissions standards through a combination of technologies:

- Diesel Particulate Filter (DPF)

- Selective Catalytic Reduction (SCR)

- Exhaust Gas Recirculation (EGR)

- Diesel Oxidation Catalyst (DOC)

- Biodiesel Compatibility: The 6.7 Powerstroke is compatible with biodiesel blends up to B20 (20% biodiesel), supporting more environmentally friendly fuel options.

Reliability and Common Issues

While the 6.7 Powerstroke has generally been more reliable than its predecessors, like any complex engine, it has had its share of issues:

- Early Turbocharger Problems: The first-generation engines (2011-2014) experienced some turbocharger failures, which were largely addressed with the switch to a more conventional VGT design in 2015.

- EGT Sensor Failures: Some units have experienced exhaust gas temperature sensor failures, which can trigger limp mode.

- Fuel System Issues: While less common than in previous Power Stroke engines, some units have experienced fuel system problems, including injector failures.

- Radiator Leaks: Some early models were prone to radiator leaks, which Ford addressed in later production runs.

Despite these issues, the 6.7 Powerstroke has built a reputation for being more reliable than the 6.0L and 6.4L Power Stroke engines it replaced.

Applications and Vehicle Integration

The 6.7 Powerstroke is primarily used in the Ford Super Duty truck line, including:

- Ford F-250 Super Duty

- Ford F-350 Super Duty

- Ford F-450 Super Duty

- Ford F-550 Super Duty

In these applications, the engine is paired with heavy-duty transmissions, typically the Ford 6R140 six-speed automatic in earlier models and the 10R140 ten-speed automatic in more recent versions. The powertrain is designed to handle extreme loads, with some configurations capable of towing over 16,000 kg (35,000 lbs) when properly equipped.

Ford 6.7 Powerstroke Engine: Reliability and Durability

The Ford 6.7 Powerstroke represents a significant diesel engine design and manufacturing achievement. Its in-house development allowed Ford to create an engine specifically tailored to the needs of their heavy-duty truck lineup, resulting in class-leading power and torque figures, improved reliability, and advanced technology integration.

From its innovative reverse-flow design to its continuous performance improvements, the 6.7 Powerstroke has set new heavy-duty diesel truck market standards. As emissions regulations become more stringent and customer expectations for power and efficiency increase, it will be interesting to see how Ford continues to evolve this powerplant to meet future challenges.

The 6.7 Powerstroke success story is not just about raw power or torque figures; it’s about a commitment to innovation, performance, and meeting the diverse needs of heavy-duty truck users. As the automotive industry shifts to electrification, the 6.7 Powerstroke legacy will influence the development of future powertrains, from advanced diesels to hybrids and fully electric systems.

Questions and Answers

What makes the Ford 6.7 Powerstroke unique compared to other diesel engines?

- This engine features a unique reverse-flow design with the exhaust manifolds in the engine valley, a compacted graphite iron block for increased strength and reduced weight, and advanced fuel injection technology allowing for multiple injection events per cycle.

How has the power output of the 6.7 Powerstroke changed since its introduction?

- The power output has increased significantly since 2011. Initially, it produced 290 kW (390 hp) and 997 Nm (735 lb-ft) of torque. The latest models (2020+) produce 354 kW (475 hp) and 1424 Nm (1050 lb-ft) of torque.

Is the 6.7 Powerstroke compatible with biodiesel?

- Yes, this engine is compatible with biodiesel blends up to B20, which is a mixture of 20% biodiesel and 80% petroleum diesel.

What are some of the key emissions control technologies used in the 6.7 Powerstroke?

- This engine uses several emissions control technologies, including a Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) with Diesel Exhaust Fluid (DEF), Exhaust Gas Recirculation (EGR), and a Diesel Oxidation Catalyst (DOC).

How does the 6.7 Powerstroke compare in reliability to previous Power Stroke engines?

- This engine is generally considered more reliable than its predecessors, particularly the 6.0L and 6.4L engines. While it has had some issues, especially in early models, many were addressed in subsequent iterations, resulting in a more robust and dependable engine overall.